At the turn of the millennium, large incumbent logistics companies were basking in the success of a tried and tested formula. It included scaling to reduce costs and putting in place rigid operating procedures to ensure service quality. They relied on deep integrations with large corporations or heavy-touch engagements with individual consumers to ensure the correct information is collected to operate their networks as planned. Inefficiencies in the system were offset by the economies of scale.

However, the playbook has now begun to change. With the increasingly pervasive presence of mobile and internet technology, and the sustained exponential growth of the ecommerce sector, logistics companies need to effectively and efficiently deal with multiple ecosystem stakeholders to ensure success. These include

- Individual customers who are used to the convenience of on-demand services

- Small businesses that are starting to question the price, speed, and quality of their existing captive partners

- Online aggregators that pit logistics companies against each other

- Gig workers ready to work for a few hours or a few days a week

- Small fleet owners who are happy to deploy their off-duty vehicles and warehouse owners looking to optimise their spare capacity

This demands an ecosystem designed for collaboration, flexibility, adaptability, and responsiveness to emergent circumstances. In the past, this may have been a pipe dream requiring the cloning of the smartest, most knowledgeable and dynamic of operators, salespeople and delivery executives.

Today, however, the power of AI/ML and big data has turned this vision into tangible reality as it continues to shape the industry under the leadership of a new generation of tech-centric logistics companies.

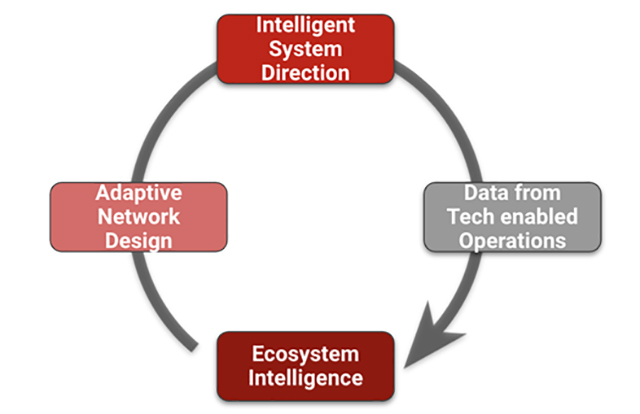

At Shipacko, we recognised early on the need for setting into motion a virtuous cycle that takes the data generated at scale, converts it into ecosystem intelligence, and provides strategic guidance for optimizing on-ground operations. The goal? Improving service quality and delivery success while enhancing the economies of scale in a manner not accessible to the traditional SOP- and asset ownership-driven operators.

Against this backdrop, here’s looking at the key components of the AI-ML/big data stack of the future:

Ecosystem intelligence

New-age logistics companies aim to become smarter and more effective with every transaction in their system. How? By harnessing huge amounts of data to extract actionable insights. The AI platform at Shipacko, for instance, ingests, assimilates and learns from over 1 billion system actions, 30 million user addresses (in conjunction with delivery coordinates), 4 billion vehicle GPS tracepoints, and 2,700 TB of computer vision data.

This data is gathered via GPS, IoT, cameras, and internet-connected devices, over a month. We then leverage it to build intelligence involving addresses, products, customer behaviour, vehicular movement, utilization, and operations in our facilities.

Adaptive network design

To grow rapidly, an organisation needs to be able to update its network design with the changing trends of the demand and supply landscape. This process includes changing the location and the capacity of facilities; determining which facilities service which locations; deciding which warehouses to store products in; manpower required at different locations; onboarding variable supply such as delivery partners/ stores/ facilities/ fleets; changing the capacity, frequency, and connections of vehicles moving in the network, etc.

AI/ML-driven network optimisation engines leverage historic intelligence in conjunction with emergent trends and can accurately predict the performance of different network configurations. This helps to upgrade and maintain the most optimal network design over short cycles of time.

Intelligent system direction

Self-driving vehicles and completely automated warehouses have become more than mere buzzwords today. As these technologies continue to mature, the scope of optimising the lifecycle of each shipment in the network will expand. Once you have a network primed to deliver success for the present demand, there are multiple decisions to make for an individual package: where it gets picked up from? Who picks it up, and along with what other shipments? What route does it move through in the network? At what time does it get delivered? These decisions, in turn, contribute heavily to the golden metrics of cost and service quality. Instead of rigid, static mechanisms to drive these activities, we rely on intelligent system direction that accounts for the current state of the network and provides the optimal guidance, all the while learning from the impact of its recommendations.

The big picture: How does it all tie in?

Let us follow the trail of a small ecommerce company. Its warehouse is in Bengaluru and, emboldened by democratised technology to take on the ecommerce bigwigs, it is currently involved in shipping a bottle of hair oil to a customer.

Unfortunately, due to lack of standardised processes, a lazy employee and a customer unfamiliar with ecommerce, the company provides the product description as ‘Dabur Vtika’, incorrect dimensions as ‘100cmX100cmX100cm’, weight as ‘10 kgs’ and consignee address as ‘b2 kran resdecy, gurgan’. A human who deals extensively with the company and the specific customer will know exactly what and where the company intends to ship, but a traditional logistics company may end up making very interesting errors, including miscalculating the space needed for this package, mishandling the shipment – leading to spillage of oil onto other shipments and not knowing where or by what mode to deliver this product, nor how much to bill the client.

Conversely, an AI-powered system will make sense of this unstructured information to decipher (using a deep learning-based product classifier like Shipacko’s Catfight) that the shipment comprises a hair oil product (a liquid that requires differential handling to avoid damage), and that it cannot be transported by air due to regulatory restrictions. The system predicts the weight and volume correctly based on historic knowledge of ecosystem products and the seller track record, and resolves the incomplete, misspelled address (using the Addfix address disambiguation engine) to ‘B-2, Kiran Residency, Sector 56, Gurgaon, Haryana – 122011,’ providing a geocode accurate to a few metres.

The system also predicts which facility in the recently optimised network will pick up this shipment, and which one will deliver. It can also determine that a bike, not a van, is enough to pick up the shipment based on its corrected weight and volume. The route (direct or via Mumbai, keeping in mind recent weather conditions) and specific trips (2 pm or 10 pm) taken from Bengaluru to Gurgaon will be selected depending on various factors. These include the load on the network, stress at a particular facility, connection timings, delivery deadline, and utilisation considerations. The system can also direct the operator for appropriate handling and loading of a liquid shipment to prevent damage.

Once it reaches the last mile, the slot predictor will predict the specific time that is best suited to deliver to that particular address on the given day (weekend/weekday, time of day depending on past trends and whether it is residential or commercial), and whether or not the delivery executive should carry a card machine as per the historic user preference. Finally, a dynamic route allocation and dispatching mechanism (such as Shipacko’s Flare engine) will create the optimum dispatch based on the current load and assign it to the appropriate delivery executive (on-roll agent or gig worker) based on the cost and delivery success considerations.

This is but a small glimpse of a subset of capabilities that the holy trifecta of ecosystem intelligence, adaptive network design and intelligent system direction enables modern logistic companies to deploy. It results in correct handling, minimum cost (through improved utilisation), and timely and satisfactory delivery made in the fewest attempts possible.

Democratising access to newly unlocked market segments and collaboration with ecosystem players for mutual gains are contingent on your tech capabilities. You need to be able to continuously make sense of unstructured and non-standard data, gain deep insights from the data lake, and use them to augment your operations. Finally, you need to be able to make dynamic contextual recommendations and learn from their acceptance or rejection by on-ground operators.

The future will see new-age logistics players transforming themselves into collaborative, AI-powered platforms rather than simply continuing as owners and operators of fleets and facilities. Organisations that embrace these tenets as integral to their functioning will continue to maintain a competitive edge over their peers, consolidating their leadership – technological and operational – in the market.